Article at online server Root.cz

05 December 2021

Source: Read more...

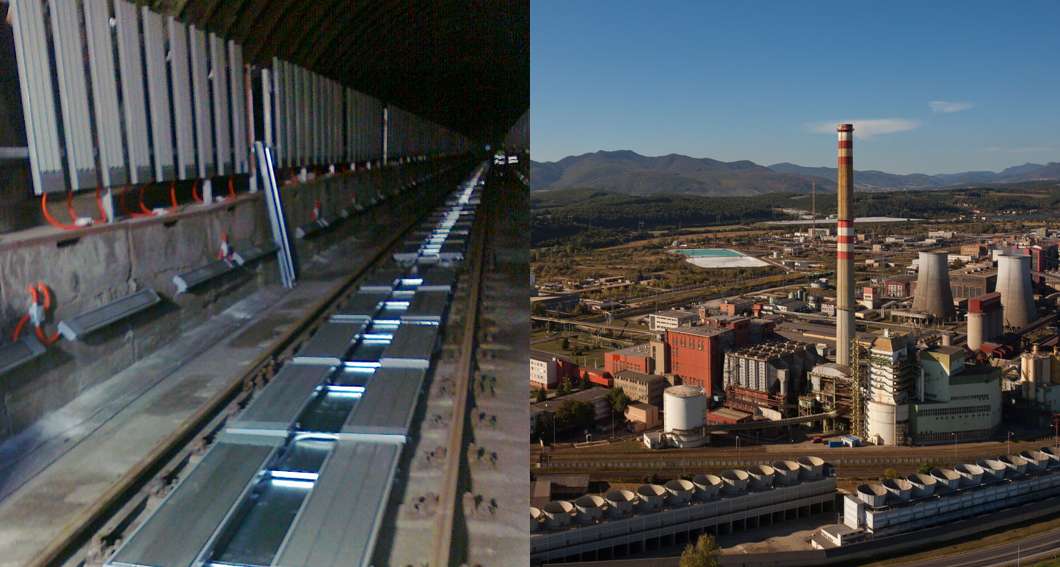

Turbine blade tilt control in a 1.5MW power plant

Following a qualified decision, the IQRF wireless technology was also used to transmit control signals for blade tilt control in power plants in Poland (JAWORZNO III). MICRORISC and IQRF Tech have implemented a tailor-made solution for their customer, Sigma Group. The previous solution, where control signals were transmitted over wires, was proved to be unreliable, so a wireless solution was sought that would work even in such a demanding environment with frequent radio signal interference due to the presence of electric motors and other sources. The system contains several IQRF transceivers located in the turbine rotor, which transmit on different channels repeatedly.

For optimal cooling, the inclination of the turbine blades and the speed of rotation change as required. The system has proven to be reliable, it has already been installed in more than 40 similar locations and many years of trouble-free operation have shown that IQRF wireless technology can be used even in the demanding conditions of heavy industry.

The company continues its custom development and offers the experience of its R&D team to new customers. You can find the contact on MICRORISC's website.

Thawing of coal in a thermal power plant

The ENO Nováky thermal power plant used a solution from a member of the IQRF Alliance, Austyn International, which deals with intelligent control of thermal systems.

They faced the problem of freezing coal, which is brought in wagons and is intended for combustion and production of electricity and heat for the Prievidza area and its surroundings. Any interruption had an impact on the continuity of supply, which was unpleasant and undesirable for the whole area.

The goal was to install a defrost system that would minimize operating costs, prevent unnecessary heat loss during defrosting, be reliable, and allow you to target exactly where defrosting should take place.

More than 550 remote control infrared radiators have been installed for optimal defrosting. Based on the measured temperature from the wireless sensors, the radiators, which target the heating exactly in the frost area are activated. The IQRF network is used for data transfer and works successfully even in this demanding environment.

The company also solves efficient regulated heating of various industrial halls and other buildings, such as hotels, schools, offices, etc., offers an environmental analysis and design of optimal solutions, even with a guarantee of return on investment. Take a look at some projects, that have been already successfully implemented and if you are interested in using such intelligent heating in your premises, do not hesitate to contact the experts from Austyn.

Data transmission from an explosive environment of product pipelines

Pipeline operators (eg for natural gas) achieve significant savings if they use a wireless solution from the company ZAT, which is used to transmit data from the so-called EX zone – an explosive environment. A previously used wire solution with the appropriate certification for this hazardous environment is very expensive. Although it is only a few meters of cable, it is still a significant cost.

ZAT supplies a sensor certified for explosive environments, equipped with IQRF wireless communication, which transmits data on the flow and temperature of the product and the condition of the dampers (closed/open) out of this secure area. The information can go by any remote wireless technology to a central monitoring application.

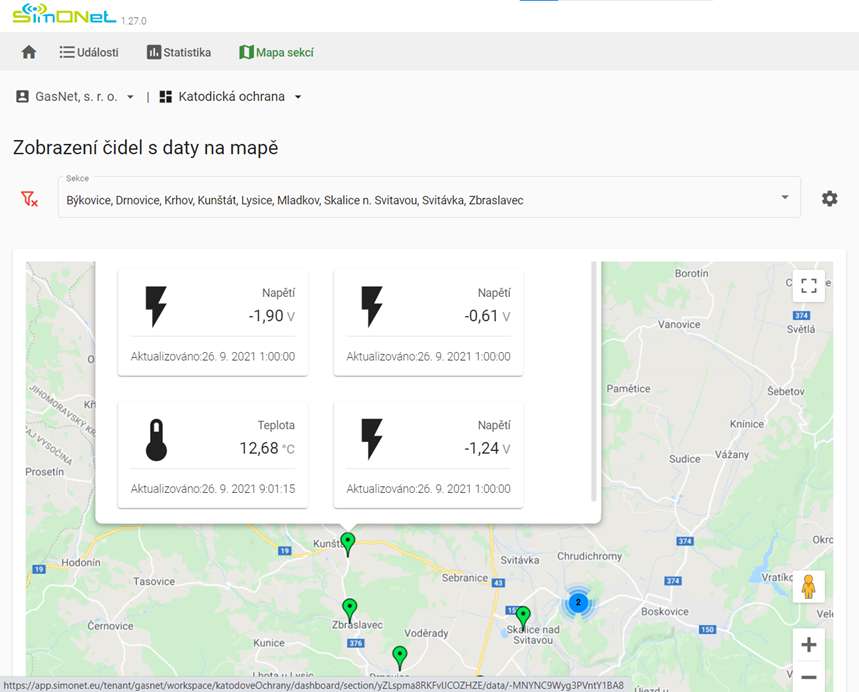

SimONet is an application that displays data from a variety of sensor types, regardless of transmission technology or manufacturer.

The picture below shows the display of data from the gas pipeline for the customer GasNet, s.r.o. By measuring the cathodic protection and changing the voltage, possible corrosion of the gas pipeline is revealed, which is undoubtedly an undesirable and dangerous condition. Everything is displayed in the application via remote data transmission, thanks to which there is an immediate overview of faults. This eliminates the need to visit the gas pipelines in person, measure and inspect everything on site, which by itself brings significant savings, regardless of the costs associated with a gas leak from a corroded pipeline or dealing with the consequences of an explosion.

Another customer, the thermal power plant in Náchod, which supplies customers with heat and electricity, uses sensors and applications from ZAT to obtain data from calorimetric meters. This saves time-consuming and costly meter readings using field staff.

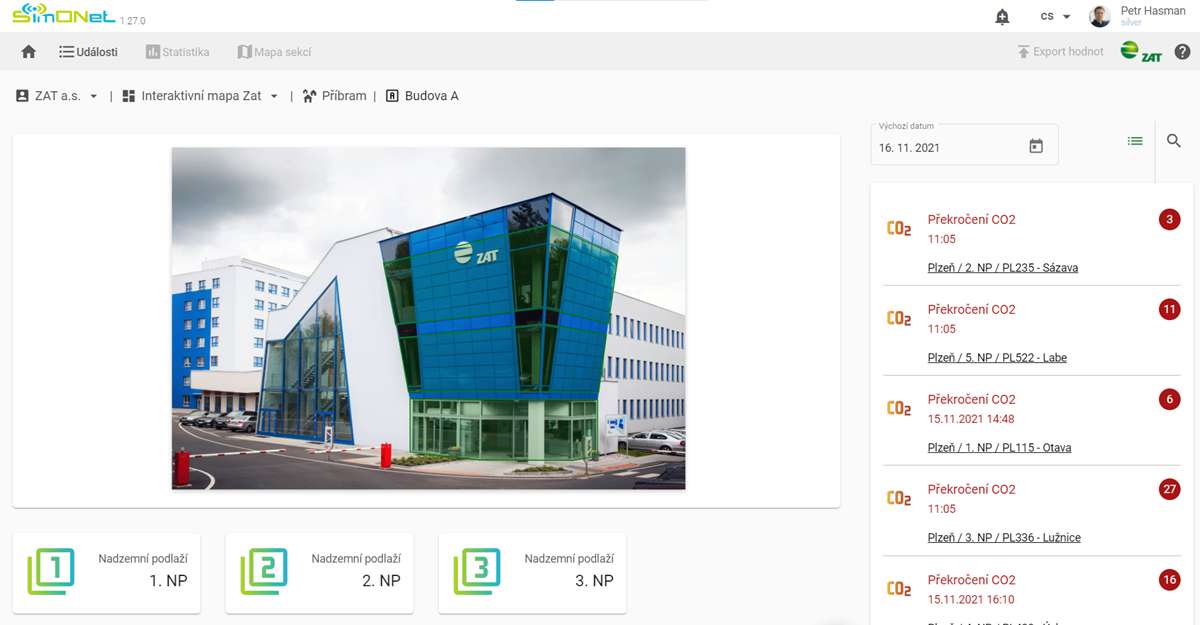

The company ZAT a.s. offers an initial analysis directly on the customer's premises, where it conducts a survey of processes and problems as part of free three-day monitoring and, based on the current situation, proposes a suitable solution, which often leads to optimization, streamlining and subsequent cost-effective and well-arranged solutions.

An example might be optimizing the layout of meetings in a company's meeting rooms. Given the current pandemic situation of COVID-19, it is appropriate to occupy only half of every room, which the SimONet system can monitor. At the time of booking, it will only offer you those rooms that correspond to the number of people who will be in the meeting and heat the room to the optimal temperature. It is also possible to track where employees are in the building and trace back whoever an infected person has encountered.

ZAT is working on optimized indoor heating in cooperation with the already mentioned company Austyn International.

Monitoring the car trailer load

Customer development with an emphasis on innovation and practical functionality is also carried out by one of the younger members of the alliance, the company JoTio Tech.

For their customer, a car trailer rental company who had a problem with their customers often overloading their rented trailers, JoTio developed a sensor to measure the load on the axle. Installation is simple and durable. This prevents destruction and at the same time, thanks to the tracking device, it is possible to find out on maps whether the trailer is being used in the location for which it was rented.

JoTio targets customers who feel the need to improve something, just don't know how. Experts from the company with experience from various projects using different technologies analyze the current situation and propose solutions. As an IoT design house, they can develop a completely new solution, from prototyping the necessary equipment, providing basic piece production, to integration into the cloud and displaying data in a mobile application. With knowledge of solutions from other members of the alliance, they are also able to use their already functional finished products and methods.

Conclusion

IQRF® wireless mesh technology can be used in a wide range of IoT projects. Thanks to the ability to work locally autonomously, it meets the safety requirements of some premises with critical conditions. The data can remain within the company, it can be processed on servers within the internal infrastructure and it is not necessary to send it to the cloud. On the other hand, if there is nothing to prevent data transfer to the cloud, the IQRF infrastructure allows it. You can remotely monitor the conditions in your building, factory, warehouse, power plant, etc.

As you could see from the examples above, technology and solutions can be combined. Contact our members if you want to consult how your operation could be optimized, monitored, managed, etc.

You can find case studies and members' products on www.iqrfalliance.org.

If you have devices that you would like to provide with IQRF® wireless communication or you have an application, IoT gateway, or customers to whom you would like to offer a suitable solution using one of the listed products, contact us. We welcome new innovative members to our community.

Ivona Spurná, ivona.spurna@iqrfalliance.org.

Other articles in this category: