Introduction

The main goal of DEPRAG CZ was to monitor the status of pneumatic tools and make recommendations regarding efficiency and cost savings. Grinders have only a little accumulator with no external electricity. Workers often use inefficient tools or processes. The status has to be under online monitoring.

Solution

The solution consists of wireless pneumatic grinding tools equipped with an electricity generator (harvesting rotating system), online dashboard with information about tools status, a whole history, recommendations for a maintenance, comparison of workers and tools and a visualization of the working process in a time scale.

Conclusion

As a result, the customer saves significant costs. Due to high-quality forecasting and monitoring, unline the repair of the whole tool, which would be much more expensive (thousands of euros), only a small part of the work tool should be changed or repaired.

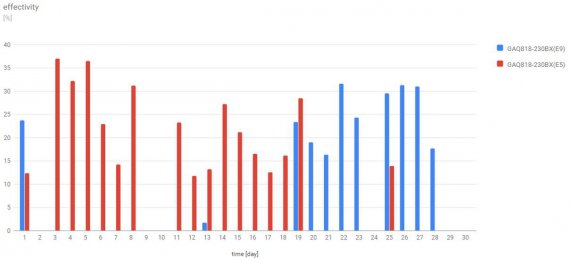

The efficiency of workers and tools is improved by continuous monitoring and recommendations.

The IQRF advantages are excellent RF specifics and a robust mesh network which allows transmitting data from tools to the central cloud system very reliably.

It does not matter if working tools are inside industry halls, huge buildings or in open space. IQRF mesh network is able to deliver data despite bad RF conditions.